Specifications:

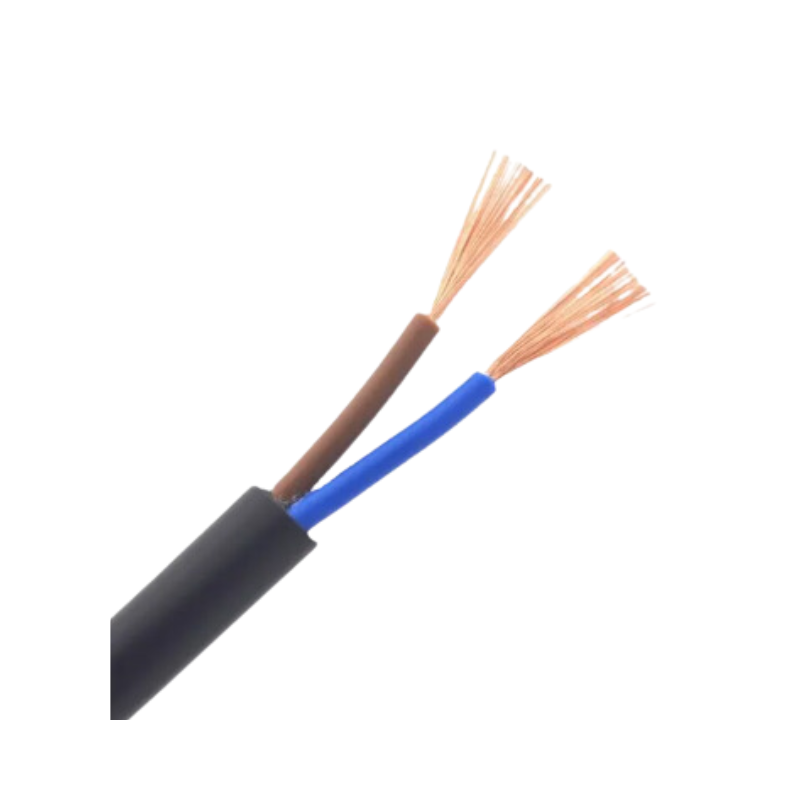

- Conductor: Typically made of copper or aluminum for optimal conductivity and flexibility.

- Insulation: Various insulation materials, such as PVC (Polyvinyl Chloride) or rubber, provide electrical insulation while allowing for flexibility.

- Stranding: The conductors are often stranded to enhance flexibility, allowing the cable to bend without causing damage.

- Jacket: A durable outer jacket, made of materials like PVC or rubber, protects the cable and enhances its resistance to abrasion and environmental factors.

- Color Coding: Some flexible cables may feature color-coded conductors for easy identification.

Applications:

- Portable Appliances: Flexible cables are commonly used in the wiring of portable appliances and devices, providing a movable and adaptable power connection.

- Power Tools: In construction sites and workshops, flexible cables are employed to power electric tools, offering flexibility and ease of movement.

- Industrial Equipment: Flexible cables are utilized in industrial machinery and equipment where constant movement and flexibility are essential for efficient operations.

- Stage and Entertainment: In the entertainment industry, such as theaters and concert venues, flexible cables are used for lighting, sound systems, and other equipment that require frequent repositioning.

- Medical Devices: Flexible cables find applications in medical equipment where pliability and adaptability are necessary for devices such as patient monitors and diagnostic tools.

- Robotics: In robotics and automation systems, flexible cables enable the movement of robotic arms and components.

- Automotive Wiring: Flexible cables are used in automotive wiring, connecting various components where movement and flexibility are required.

- Data Centers: In data centers, flexible cables are used for temporary or movable connections between servers, switches, and other networking equipment.

Reviews

There are no reviews yet.